ABOUT US

LeanProject

Many forward-thinking individuals contributed to the origin and growth of LeanProject. Both Principals of LeanProject, Klaus Lemke and Jason Klous, took different paths to become experts in lean construction and were affected by many people along the way. To understand our company, it is vital to understand the people who shaped our philosophy, including a brief explanation of our backgrounds and journey.

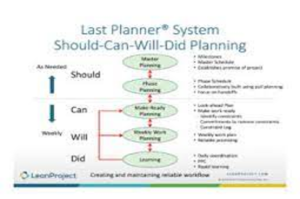

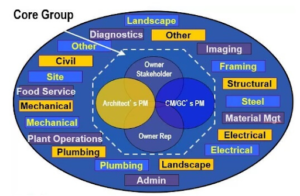

LeanProject was born together with Lean Construction Institute, or LCI. Greg Howell, Glenn Ballard and others started LeanProject to leverage lean thinking on projects in the engineering, architectural and construction industries. They developed and refined the Last Planner ® System, and this grew into organization transformation and integrated project delivery (IPD) developments. Greg and Glenn were the original lean construction consultants and blazed the path that Klaus and Jason continue today.

Our Combined Journey

LeanProject’s owners share a common philosophy and mission, but come from different backgrounds and experience. Klaus Lemke comes from a strong engineering and management background, while Jason Klous worked in construction most of his life as a superintendent and pursued an education in construction management. Each brings a unique perspective and experience in the industry that are valuable and can help our clients achieve their optimization goals.

Klaus Lemke

Klaus’ education background includes a civil engineering degree from the University of Illinois, which steered his career path to structural design and construction management. When Klaus decided to pursue his MBA at Marquette University, he first learned about lean thinking and began his journey toward becoming involved with LCI and working with Greg Howell, eventually becoming the managing principal at LeanProject. Klaus is an industry leader in lean construction and the author of Better Building: Lean Practice for the Project-Driven Organization.

Jason Klous

Jason started his journey toward lean construction earlier than most, working in construction as a teenager and becoming a journeyman carpenter in his twenties while working his way through college. Jason received his degree in construction management from the University of Minnesota. When Jason pursued his MBA, he was introduced to lean thinking, which eventually steered him toward LCI and his introduction to Klaus. After studying with Dr. Fernando Flores Jason was inspired to pursue a Ph.D in Lean Construction with a focus on transforming teams using the Language Action Perspective.

OUR HISTORY

Two Backgrounds, One Mission

Klaus and Jason have very different backgrounds, but they share the same passion for lean thinking and applying it to the projects and organizations that need their help. Klaus has an intricate understanding of construction management and engineering, while Jason has spent most of his life working in the construction trenches and is passionate about giving a voice for tradespeople.

Both were frustrated with the inconsistencies and lack of organization within the construction industry, in management and on the jobsites. With their combined experience and education, they offer an unmatched level of expertise in lean construction, Last Planner System, pullpole planning and lean leadership for mega projects in multiple industries.

Not only are Klaus and Jason partners in LeanProject, but the two are friends and linked by a strong personal bond. Since 2014, they have worked together closely, even working abroad in Ireland and Israel to consult on international projects. Both intensely care about helping people and finding ways to save projects or organizations that are failing. Both are intrigued and influenced by the work of Dr. Fernando Flores. The work-life balance and shared history of our owners is part of what makes our team at LeanProject exceptional at what we do – it is more than just a job or career to us; it is our passion.

TIMELINE STORY

Our History